1. Introduction

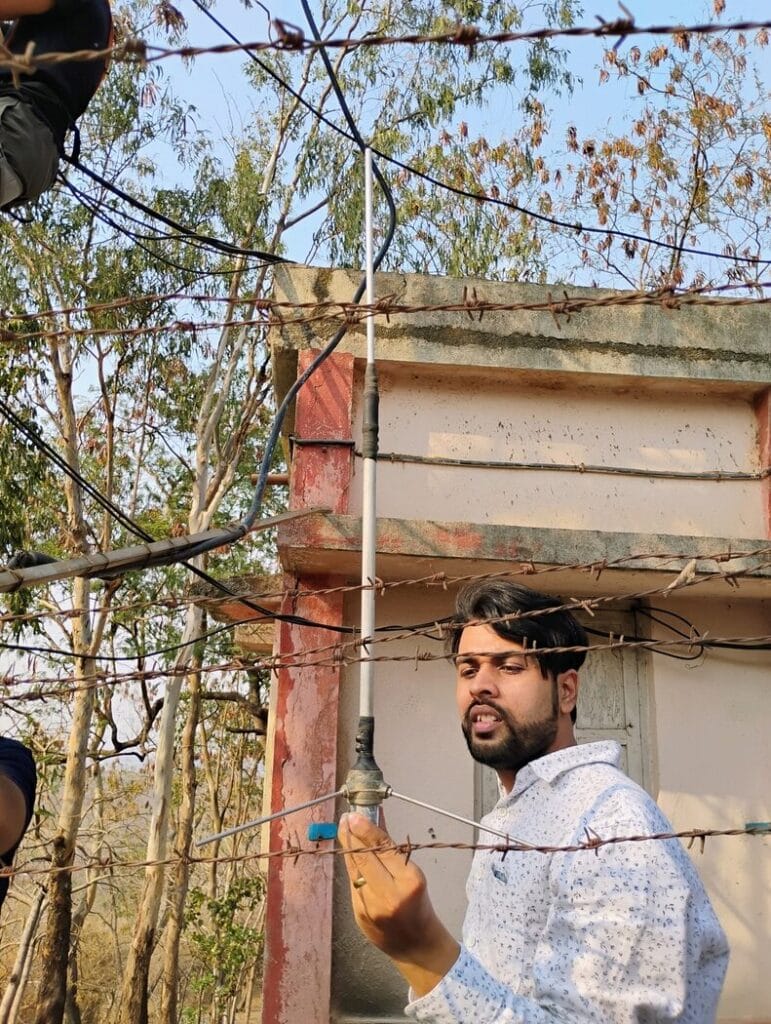

The UHF repeater had been experiencing persistent technical issues, severely limiting its operational capability and rendering QSOs (contacts) impossible. To resolve these problems and restore optimal performance, a comprehensive maintenance operation was undertaken. This initiative was spearheaded by OM Prateek (VU3YEK) and executed with the support and collaboration of the team.

Following a meeting conducted on Sunday, 2nd March 2025, OM Prateek (VU3YEK) encouraged HAMs and Shortwave Listeners (SWLs) to assess the UHF repeater site for an in-depth analysis. Consequently, maintenance activities were carried out on 2nd March 2025, 9th March 2025 and 10th March 2025.

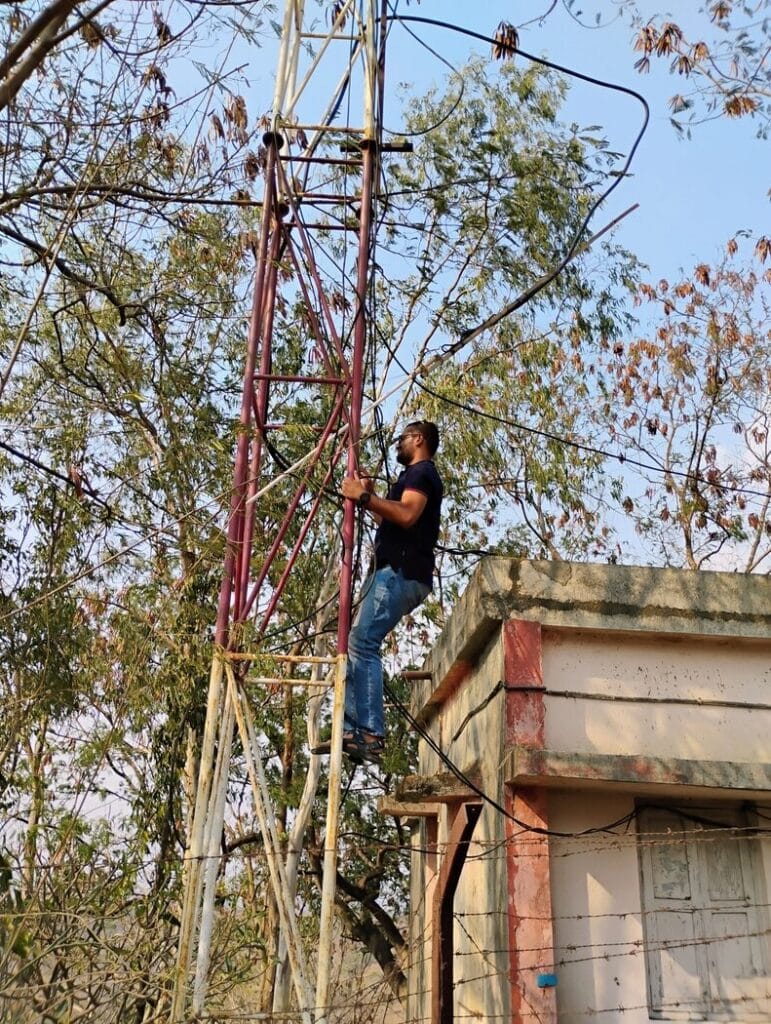

A notable contributor to the maintenance effort was OM Pushkaraj Patel (VU3GDQ), whose expertise and dedication in climbing the tower and executing the necessary adjustments were instrumental. OM Pushkaraj Patel (VU3GDQ) is a professional fitness trainer, outdoor educator, and partner in Climbcraft, a climbing training facility located on Prabhat Road, Pune(https://www.instagram.com/climbcraftpune).

2. Team Contributions

- OM Prateek (VU3YEK): Initiator and coordinator of the maintenance activity.

- OM Pushkaraj Patel (VU3GDQ): Provided essential expertise in tower-climbing and ensured all safety protocols and procedures were adhered to. Also he fixed the UPS battery connector which was loose.

- OM Fadrick (VU3DTT) and OM Gaurav (SWL): Actively contributed by offering technical support and insightful suggestions throughout the maintenance process.

- OM Kunal (VU3YEJ): Contributed by offering technical and physical support by identifying correct antenna during the critical moment. Also observed and documented the whole process through photography.

3. Key Maintenance Activities

- Antenna Replacement: One of the antennas was not performing as expected. This antenna was replaced.

- Visual Inspection: The other antenna and associated components were thoroughly examined for signs of physical damage, corrosion, or misalignment. Red electrical tape pieces have been applied throughout the length of the co-axial cables for easier identification in future.

- Cleaning: Dirt, debris, and external contaminants were meticulously removed to prevent interference with signal integrity.

- Connection Integrity: Cable connections and joints were inspected and tightened to prevent electrical faults or signal degradation. Co-axial cables were examined, electrical tape was applied to places where the outer layer seemed damaged. Both coaxial cables were initially bound together with iron binding wire at places for easy identification and handling. However, it was found that the wire was damaging the coax. A feedback issue was also observed. Both coax cable have now been separated and marked with red electrical tape.

- Structural Integrity: The stability of the tower and its mounting brackets was assessed, with reinforcements applied where necessary.

- Signal Testing: Rigorous testing of the antenna’s performance was conducted to ensure effective transmission and reception.

- Weatherproofing: Basic measures, including electrical tape, were employed to fortify the system against adverse weather conditions, specifically in preparation for the monsoon season of 2025.

4. Safety Protocols

The following measures were implemented to uphold the highest safety standards:

- Utilization of appropriate safety gear, including harnesses and helmets, for personnel working at height.

- Adherence to standard operating procedures and clear communication protocols to mitigate risks.

- Maintenance of a comprehensive checklist to ensure that all critical steps were executed systematically.

5. Conclusion

The maintenance operation was successfully executed through the collective efforts and collaboration of all team members. Particular commendation is due to OM Prateek for his leadership and OM Pushkaraj for his exceptional role in ensuring the operational success of the UHF repeater. The system is now restored to optimal functionality, evident from its improved performance and minimized transmission tail, signifying a well-executed repair.

During the process, it was observed that the transmission cable sustained damage, which has been temporarily mitigated using electrical insulation tape until a replacement cable can be procured. Additionally, the transmission antenna was repositioned and replaced with a Diamond X50 model, while the removed antenna was found to have anomalous SWR readings upon testing with a NANO VNA. The latter has been earmarked for further investigation.

The team extends its gratitude to the following individuals for their invaluable assistance in testing and observations:

- OM Sooraj (VU3ZAG)

- OM Siddharth (VU3EQX)

- OM Ajit Karnik (VU2AMK)

- OM Vishal (VU3VJS)

- OM Milind (VU2MSB)

Additional acknowledgment is extended to:

- OM Ranjit (VU3TOH) and OM Gaurav (SWL) for their detailed observation reports via SDR and handheld devices. Thanks to OM Vilas (VU2VPR), OM Mangesh (VU2OOM) and OM Nitin (VU2CAN) for their guidance & support.

Last but not least, a special acknowledgement to the following members of the Hams of Pune Group who willingly came forward and generously contributed towards the cost of the replacement antenna.

- VU3YEJ

- VU2NAK

- VU3VJS

- VU2BQL

- VU3IFQ

- VU2VPR

- VU2DU/W3

- VU2MSB

- VU3EQX

- VU2SIJ

- VU2UDD

- VU3MRG

- VU3YYO

- VU3IZK

- VU3HAJ

- VU3SZO

- VU2DVW

- VU2AMK

- VU3RAZ

- VU3YEK

- VU3FML

- VU3GDQ